描述

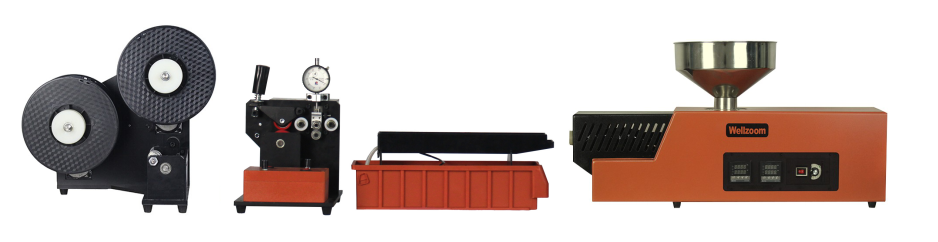

It’s the third generation extruder line – Wellzoom E desktop extruder line, its advantages are reflected in the following aspects:

- The extrusion speed can reach up to 6.5 meters/minute (Or, about a kilogram of PLA@50 minutes).

- The new extruder added mixing screw thread to make mixing different materials easier.

- Original online auxiliary measurement function. Makes the desktop extruder precise control wire diameter with a low-cost auxiliary detection method.

- The material has a wide range of applications. Has been successfully used in low temperature material PCL (60℃) extrusion, medium temperature material nylon, PC, ABS, PLA, and high temperature materials such as PEI, PEEK extrusion.

- High reliability. After a long period of trial and error and adjustment of the multi-dimensional extrusion parameters, the extruder has a very high reliability;

- With the twin-shaft winding machine, you can easily replace the coil without affecting normal machining.

- The desktop line is also equipped with a meter counter to facilitate mass production.

- In order to adapt to different materials, provide a variety of cooling combination options (specific requirements can consult wellzoom team).

Parameters:

- Maximum extrusion speed: 6500 mm/min

- Suitable materials: ABS, PLA, Nylon, wood plastic, PVA, PS and so on

- Operating temperature: below 320℃(maximum 450℃ or 600℃ need customizing)

- Temperature zone: 2 temperature zones (independent control)

- Accuracy of filament: ±0.05@1.75mm; ±0.13mm@3.00mm

- Power requirement : 220V, 50Hz (110V, 50Hz need customizing)

- Power: 360W-560W

- Nozzle: 2 (2.2mm, 3.2mm)

Wellzoom E extruder:

- Simple appearance, easy to operate.

- Energy efficient.

- Easy to clean the material cavity and change the nozzle.

- Special screw, high efficiency extrusion.

- Can adapt to most of thermoplastic materials.

- Can modulate color. It can meet your needs about the color and material of filament.

- Large-capacity hopper, the particles after baking can be directly poured into the hopper for processing.

- Dual-zone & independent temperature control can meet the requirement better to composite material.Preheat zone is for melting materials.Extrusion zone is for controlling extrusion temperature.

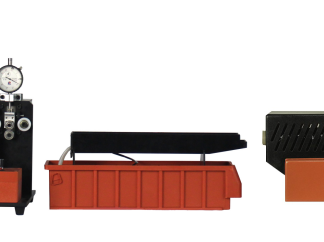

Water-cooling tractor

- Stepping motoris used to ensure stable traction speed.

- Stepless speed control.

- On-line measurement function.

- There is a meter counter. Length measurement can be performed to control the weight of each coil. To bring the convenience for the mass production of filament.

- A variety of cooling combinations can be chosen. We can provide the best solution.

Auto winder

- Match the extrusion speed of the extruder automatically.

- The arranging mechanism can arrange the filament in order.

- The arrange range can be adjusted to adapt to different reels.

- Reel speed can be adjusted.

- With dual-axis winder, you can easily replace the reel without affecting normal machining.

评价

目前还没有评论